-40%

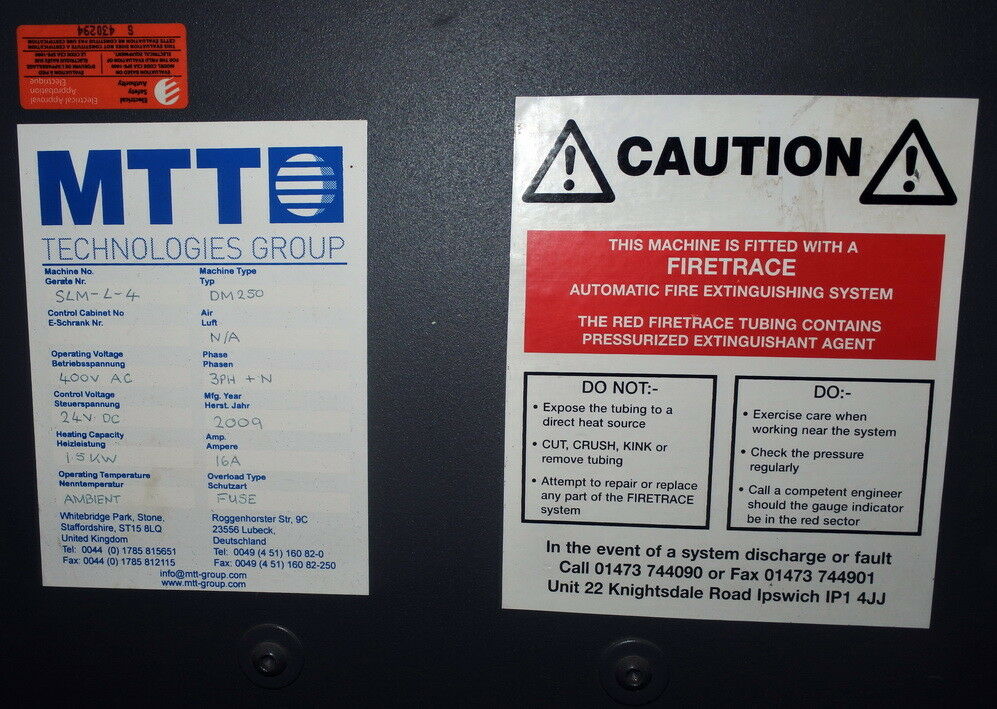

Metal 3D printer, Sinterstation DM-250, Renishaw, 3D Systems, SLM , DMLS, MTT

$ 73656

- Description

- Size Guide

Description

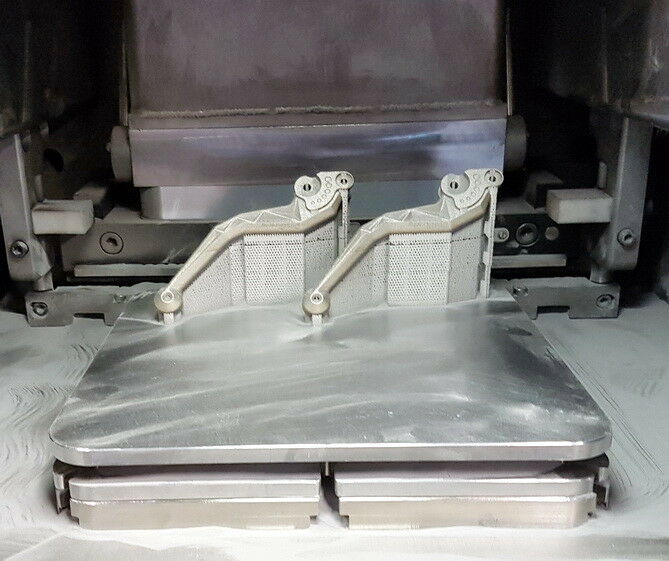

For sale, used Direct Metal Laser Sintering System in excellent working condition. This machine is fully operational and under power producing parts for our ongoing operation. The machine is currently running 316 Stainless Steel and Maraging Steel in both, Nitrogene and Argon environment. It comes with the Renishaw software package.If you decide to purchase the machine we will be happy to offer a training so you how to operate it, as well as provide you with all build parameters so your builds come right the first time, every time.

We are

not

a machinery dealer who sells it on consinment. We are a 3D printing service bureau and use this machine for our day to day operation. However we are upgrating to a newer model, therefore have to part with it, so we can create the space and ease our cash flow.

Last year this machine produced a replica of Mark-Antony's ancient Roman helmet. (see pictures in the gallery) This helmet has been fully 3d printed in Stainless Steel, afterwards plated with 24 carat Gold and Nickel. The helmet has been recognized by the Additive Manufacturing User Group (AMUG) where it won the prestigious first place award in advanced finishing competition.

This machine has been manufactured in 2009 and has a very strong laser beam.

The oxygen sensors are new and freshly calibrated.

It is under power and available for viewing in our Toronto facility or for producing a sample as per your STL file*.

We will be happy to supply the buyer with a box of new filters to speed up the initial runs of the system.

The listed price includes professional crating and delivery anywhere in the continental North America.**

The Sinterstation

D

M250

is designed for the production of medium size components with high precision and surface quality. This 3D printer is compatible with

Tool Steel, Stainless Steel, Inconel, Cobalt Chrome, Aluminum, Titanium etc.

This is an industrial 3D printer, which uses the Selective Laser Melting (SLM) 3D printing technology. The SLM technology melts and fuses metallic powders with a

200W ytterbium fibre laser

beam. Once a layer of solid metal is created, the tray holding the 3D print is lowered and powder is layered on top.The sintering with the laser resumes for a new layer. Layer after layer the object is 3D printed, until completion.

The

D

M250

features an external powder hopper with valve interlocks to allow additional material to be added whilst the process is running. It is possible to remove the hopper for cleaning or to exchange with a secondary hopper for materials change. This means that multiple material types can be interchanged on the AM250 platform with relative ease. The powder overflow containers are outside the chamber and have isolation valves so that unused materials can be sieved and reintroduced to the process via the hopper while the system is running. The system has a build volume of

250 mm × 250 mm × 300 mm.

DM 250 system features a vacuum chamber evacuation followed by high purity argon or nitrogen gas in order to create a high quality atmosphere, crucial when building in reactive materials such as titanium, where oxygen content must be minimized.

The DM250 has been designed for series production of implantable devices as well as prototypes of complex lattice structures or detailed aerospace geometries.

*

Sample printing is not a free service

** please contact us for shipping quote outside North America